ls polyester yarn bad for the environment?

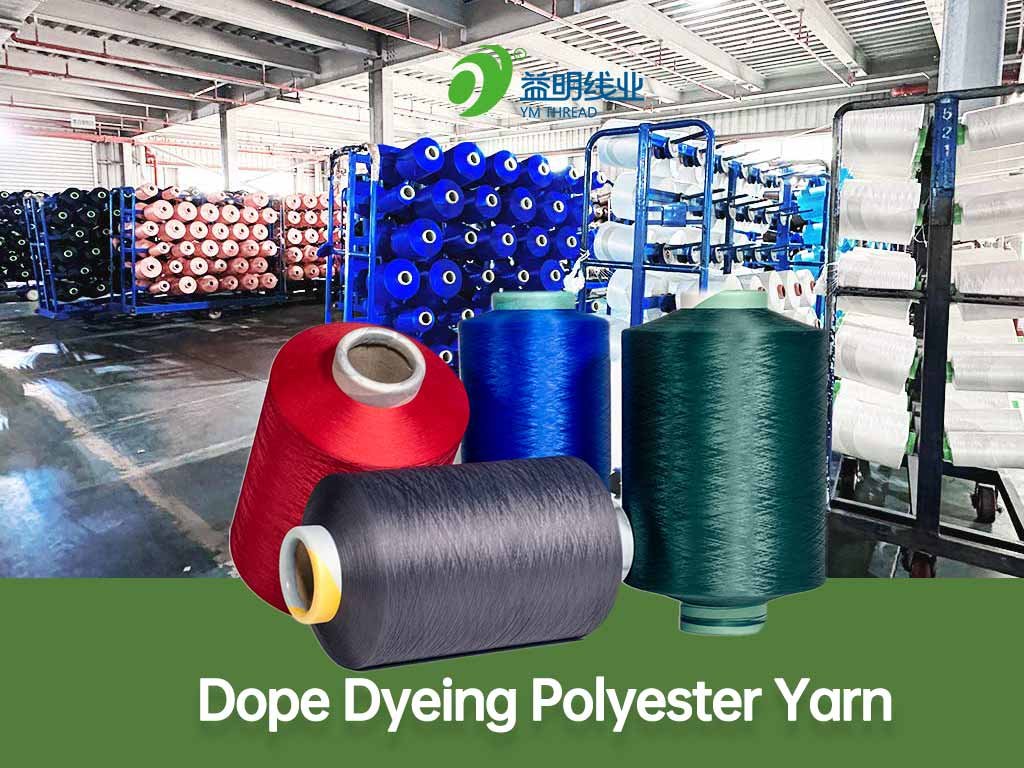

一、Color Masterbatch Spinning (dope dyeing)

Color spinning with masterbatch is a process where colorants (masterbatch) are directly added to the polymer, which is then spun to form colored fibers. This method is an environmentally friendly technology used in the textile industry for the production of colored polyester fibers. During the masterbatch spinning process, the masterbatch is thoroughly mixed with the polyester polymer. Subsequently, the mixture undergoes melting, stretching, and cooling in the spinning machine to form continuous colored fibers.

(一) Advantages for environment

- Efficiency: Color masterbatch spinning, where color is added to the polymer before spinning, can be more efficient as it integrates the coloring process into the spinning, reducing the need for additional dyeing steps.

- Reduced Chemical Use: This method requires fewer chemicals compared to traditional dyeing, as the color is mixed with the polymer itself, potentially leading to less environmental pollution.

- Consistency: The color is uniformly distributed throughout the fiber, which can lead to less variation in the final product and less waste due to color inconsistencies.

- Sustainability: The use of recycled materials, such as rPET, in the masterbatch process can contribute to a circular economy and reduce the carbon footprint.

(二) Disadvantages of Color masterbatch spinning

- Limited Color Range: The color options might be more restricted compared to traditional dyeing, which could be a limitation for certain applications.

- Higher Initial Costs: The equipment and technology for color masterbatch spinning can be more expensive upfront, which may be a barrier for some manufacturers.

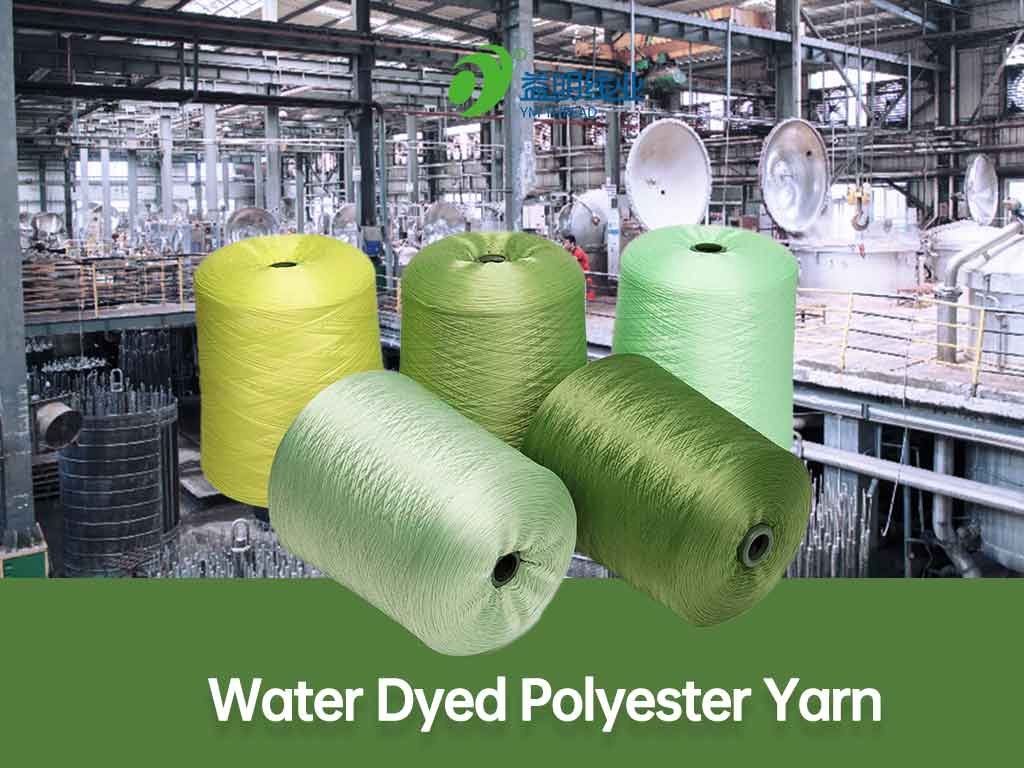

二、Water Dye (Traditional Dyeing Process)

Water-dyed yarn is a traditional dyeing method that involves coloring yarn or fabric by immersing it in an aqueous solution containing dyes and chemical auxiliaries. This process typically includes several steps such as pre-treatment, dyeing, post-treatment, and drying. Water dyeing technology can provide a wide range of colors and patterns for the yarn as needed, but it also presents some environmental challenges, such as water consumption, the use of chemical dyes, and wastewater treatment issues.

(一) Disadvantages of Color masterbatch spinning

- Water Consumption: Traditional dyeing processes can consume significant amounts of water, which can strain local water resources, especially in water-scarce regions.

- Chemical Pollution: Dyeing involves the use of various chemicals, including dyes and other additives, which can be toxic and harmful to the environment if not properly managed. The release of these chemicals into waterways can harm aquatic life and disrupt ecosystems.

- Color Fastness Issues: Dyeing can sometimes result in color fastness issues, leading to fading and color bleeding during washing, which can release microfibers and contribute to water pollution.

- Energy Intensity: High-temperature processes are often required for dyeing, particularly for synthetic fibers like polyester, which can be energy-intensive and contribute to higher carbon emissions.

- Waste Generation: The dyeing process can generate waste in the form of leftover dye baths and chemical waste, which must be properly treated and disposed of to prevent environmental harm.

(二) Advantage of Water Dye

- Water Usage: Water dyeing can consume significant amounts of water, which can be a concern in areas where water is scarce.

- Chemical Pollution: The process often involves the use of various chemicals, which can be harmful to the environment if not properly managed.

- Color Fastness: Dyed polyester may not have the same level of color fastness as color masterbatch spun yarns, leading to potential color fading and microfiber release during washing.

- Energy Consumption: The dyeing process often requires high temperatures, which can increase energy consumption and carbon emissions.

三、Summarize

In conclusion, while both color masterbatch spinning and water dyeing have their respective environmental impacts, the choice between the two methods should be based on a balance of sustainability, cost, design flexibility, and the specific requirements of the end product. The textile industry is continuously evolving, and there is a growing trend towards more sustainable practices, which may influence the adoption of one method over the other.

Ymthread Common Specifications

(一) Color Masterbatch Spinning Yarn

| Application | Common specifications |

| fly-knit shoe uppers | 150d/36f,300d/72f |

| webbing | 150d/36f,300d/72f |

| shoeslace | 150d/36f,300d/72f |

| collar | 150d/36f,300d/72f |

| rib | 150d/36f,300d/72f |

| overlocking | 150/36f |

| gloves | 150d,150d/36f |

| carpet | 600d,900d |

(一) Water Dye Yarn