What is 100% dope dyed polyester yarn?

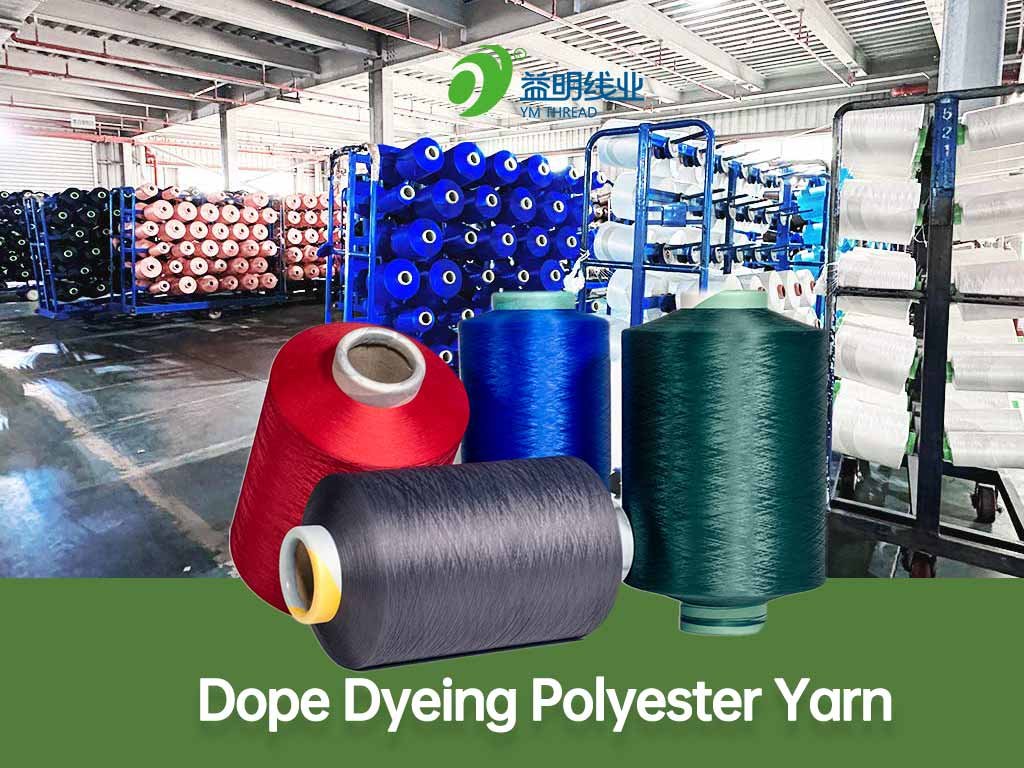

Introduction

The textile industry is constantly evolving, with innovations in materials and processes that aim to improve both the quality of the final product and the sustainability of the production process. One such innovation is the use of 100% dope dyed polyester yarn, which has gained significant traction for its numerous benefits.

This article delves into what exactly dope dyed polyester yarn is, its advantages, and how it contributes to a more sustainable future in the textile sector.

What is Dope Dyeing Meaning

Polyester yarn is a synthetic fiber known for its strength, elasticity, and versatility. Traditionally, polyester yarn is dyed after it has been extruded, a process that can be resource-intensive and lead to color inconsistencies. However, with dope dyeing, the color is added to the polymer before the yarn is spun, resulting in 100% dope dyed polyester yarn.

Dope Dyeing Process

The process of dope dyeing of polyester involves the following steps:

- Polymerization: The polyester polymer is created through a chemical reaction.

- Dyeing: While the polyester is still in a molten state, pigments are added and mixed thoroughly to ensure a uniform color distribution.

- Spinning: The colored polymer is then spun into yarn, maintaining the consistent color throughout the entire length of the yarn.

Advantages of 100% Doppe Dyed Polyester Yarn

- Consistent Color: The dope dye is present throughout the entire yarn, eliminating the need for additional dyeing processes and ensuring a uniform color without the risk of fading or color bleeding.

- Efficiency: The process is more efficient as it eliminates the need for separate dyeing, reducing both time and labor costs.

- Environmental Benefits: By integrating the dyeing process into the initial polymer creation, less water and energy are used, and there is a significant reduction in wastewater and chemical use, contributing to a smaller environmental footprint.

- Cost-Effective: The reduced need for additional dyeing and finishing processes can lead to cost savings for manufacturers.

- Design Flexibility: With dope dyed yarn, designers have the freedom to create intricate patterns and color combinations without worrying about the dyeing process affecting the final design.

Applications of 100% Doppe Dyed Polyester Yarn

Dope dyed polyester yarn is used in a wide range of applications due to its properties:

- Flyknit upper shoes:Used for shoe uppers because of its rich color and high durability and strength.

- Apparel: In clothing for its durability and colorfastness.

- Home Textiles: For bedding, upholstery, and curtains for their easy maintenance and vibrant colors.

- Technical Textiles: In applications requiring strength and color retention, such as sportswear and outdoor gear.

Sustainability and the Future

The use of 100% dope dyed polyester yarn is a step towards a more sustainable textile industry. By reducing the environmental impact of dyeing and offering a high-quality product, it aligns with the growing consumer demand for eco-friendly products. As technology advances, it is expected that dope dyed yarns will become even more prevalent, offering a wider range of colors and applications while maintaining their sustainability edge.

Conclusion

100% dope dyed polyester yarn represents a significant advancement in textile technology. It offers a sustainable alternative to traditional dyeing methods, ensuring a consistent and vibrant color in the final product. As the industry continues to seek out eco-friendly solutions, the adoption of dope dyed yarn is likely to grow, leading to a greener and more colorful future for textiles.

Ymthread Common Specifications

| Application | Common specifications |

| fly-knit shoe uppers | 150d/36f,300d/72f |

| webbing | 150d/36f,300d/72f |

| shoeslace | 150d/36f,300d/72f |

| collar | 150d/36f,300d/72f |

| rib | 150d/36f,300d/72f |

| overlocking | 150/36f |

| gloves | 150d,150d/36f |

| carpet | 600d,900d |