What is the difference between latex and spandex?

一、Latex and spandex

Latex and spandex are both synthetic materials commonly used in the textile industry, but they serve different purposes and have distinct properties. This article aims to shed light on the differences between these two materials, their uses, and their characteristics.

(一)Introduction

Before diving into the differences, let’s briefly define what each material is:

- Latex: A milky fluid found in certain plants, such as the rubber tree (Hevea brasiliensis), which is used to produce natural rubber.

- Spandex: A synthetic fiber known for its exceptional elasticity, often used in the production of stretchable fabrics and clothing.

(二)Differences

1. Composition

- Latex is a natural polymer derived from the sap of rubber trees. It contains a complex mixture of organic compounds, primarily polyisoprene, which is a polymer of isoprene.

- Spandex, on the other hand, is entirely man-made. It is a segmented polyurethane, which means it consists of a chain of molecules with alternating soft and hard segments.

2. Elasticity

- Latex is elastic but not as much as spandex. It can stretch and return to its original shape, but the elasticity is not as strong or consistent as that of spandex.

- Spandex is renowned for its high elasticity. It can stretch up to 500-700% of its original length without breaking and still return to its original form.

3. Uses

- Latex is primarily used in the production of natural rubber products such as tires, gloves, and medical devices. It can also be found in latex paints and other industrial applications.

- Spandex is predominantly used in the textile industry, particularly for clothing items that require a high degree of stretch, like leggings, sportswear, and swimwear.

4. Durability

- Latex products can be quite durable, especially when vulcanized to create rubber. However, they can degrade over time when exposed to oxygen, heat, and sunlight.

- Spandex fibers are also durable but are more resistant to environmental factors like heat and sunlight. They maintain their elasticity for a longer period compared to latex.

5. Comfort

- Latex can be less comfortable against the skin due to its rigidity and lack of breathability.

- Spandex is known for its softness and comfort. It is breathable and conforms to the body, making it ideal for clothing.

6. Environmental Impact

- Latex, being a natural product, has a lower environmental impact compared to synthetic materials. However, the process of harvesting latex can be labor-intensive and potentially harmful to the rubber trees if not done sustainably.

- Spandex production involves chemical processes that can have a significant environmental footprint. The use of petroleum products and the release of greenhouse gases during manufacturing are concerns.

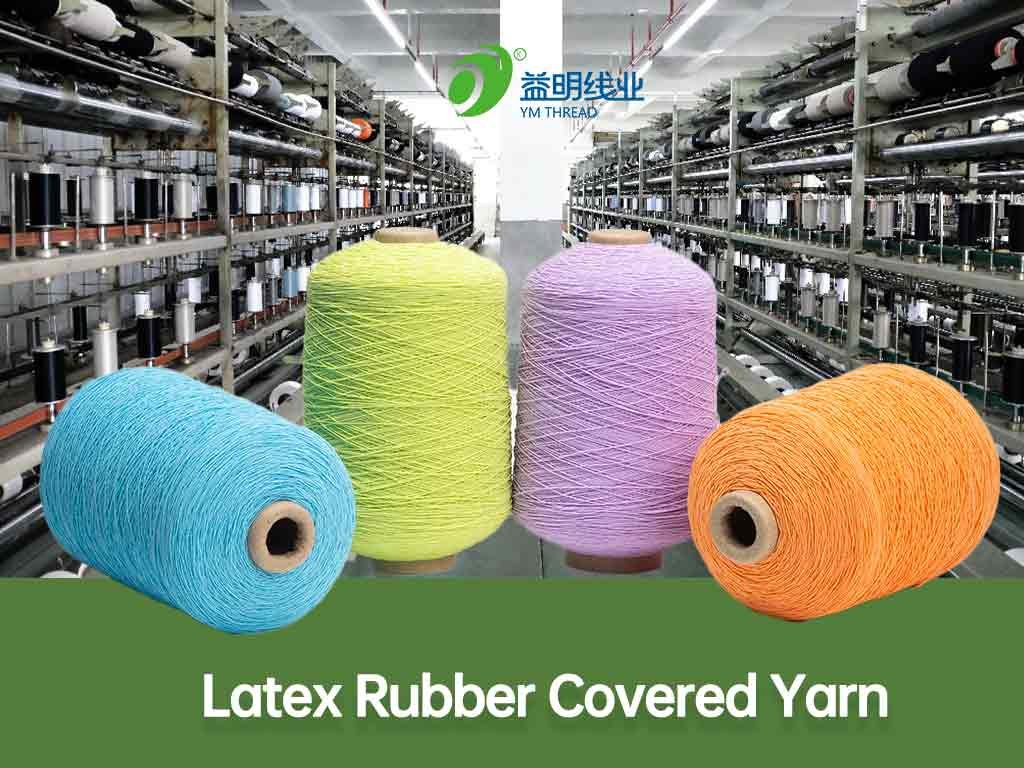

二、Latex Rubber Covered Yarn and Spandex Covered Yarn

When comparing the performance and applications of latex rubber covered yarn and spandex covered yarn, several factors come into play, including their mechanical properties, comfort, and suitability for various end products.

(一)Differences

1. Mechanical Properties

- Latex Rubber Covered Yarn: This type of yarn is known for its good abrasion resistance and grip. The latex rubber coating provides a firm and durable covering that can withstand friction and wear. This makes it suitable for applications where strength and durability are required.

- Spandex Covered Yarn: Spandex covered yarn excels in stretchability and recovery. The spandex coating allows the yarn to stretch significantly without losing its shape, which is ideal for applications requiring a high degree of flexibility and a close fit.

2. Comfort and Feel

- Latex Rubber Covered Yarn: While durable, latex rubber can be less breathable and may not conform as closely to the body as spandex. It might be used in applications where a firm grip is more important than comfort, such as in certain types of gloves or industrial textiles.

- Spandex Covered Yarn: Spandex is favored for its soft, comfortable feel against the skin. It is breathable and provides a snug fit, making it perfect for activewear, swimwear, and intimate apparel where comfort and a second-skin feel are desired.

3. Application Products

- Latex Rubber Covered Yarn: Common applications include rubberized fabrics for wet suits, gloves, and industrial rubber goods. It can also be found in the production of some types of hosiery and medical garments where a combination of strength and elasticity is needed.

- Spandex Covered Yarn: Spandex covered yarn is widely used in the fashion and sportswear industries. It is a key component in leggings, sports bras, swimsuits, and shapewear. Its high elasticity makes it indispensable for any garment that needs to move with the body without losing its shape.

4. Durability and Care

- Latex Rubber Covered Yarn: Products made with this yarn may require specific care to maintain their durability. They might not be as resistant to certain chemicals or extreme temperatures as spandex products.

- Spandex Covered Yarn: Spandex is generally more resistant to environmental factors, but it can lose its elasticity over time, especially with frequent washing and exposure to heat. Proper care is essential to prolong the life of spandex garments.

(二)Conclusion

In conclusion, the choice between latex rubber covered yarn and spandex covered yarn depends on the desired balance of strength, elasticity, comfort, and intended use. Latex rubber covered yarn is favored for its durability and grip, while spandex covered yarn is chosen for its exceptional stretch and comfort, making it ideal for form-fitting and activewear garments.

Ymthread Common Specifications

(一) Spandex Covered Yarn

| Application | Common specifications |

| fly-knit shoe uppers | 140D/75D/75D,210D/150D/150D,280D/150D/150D |

| webbing | 210D/150D/150D,280D/150D/150D,420D/150D/150D,560D/150D/150D |

| gloves | 210d,280d |

(一) Rubber Covered Yarn