Dyed Polyester Yarn

Polyester sewing thread, made of 100% polyester fiber, abrasion resistant and durable, not easy to break. Resistant to heat and chemicals, suitable for all kinds of fabrics, with elasticity, keep the sewing thread firm. Widely used in clothing, home textiles, industrial products and other manufacturing.

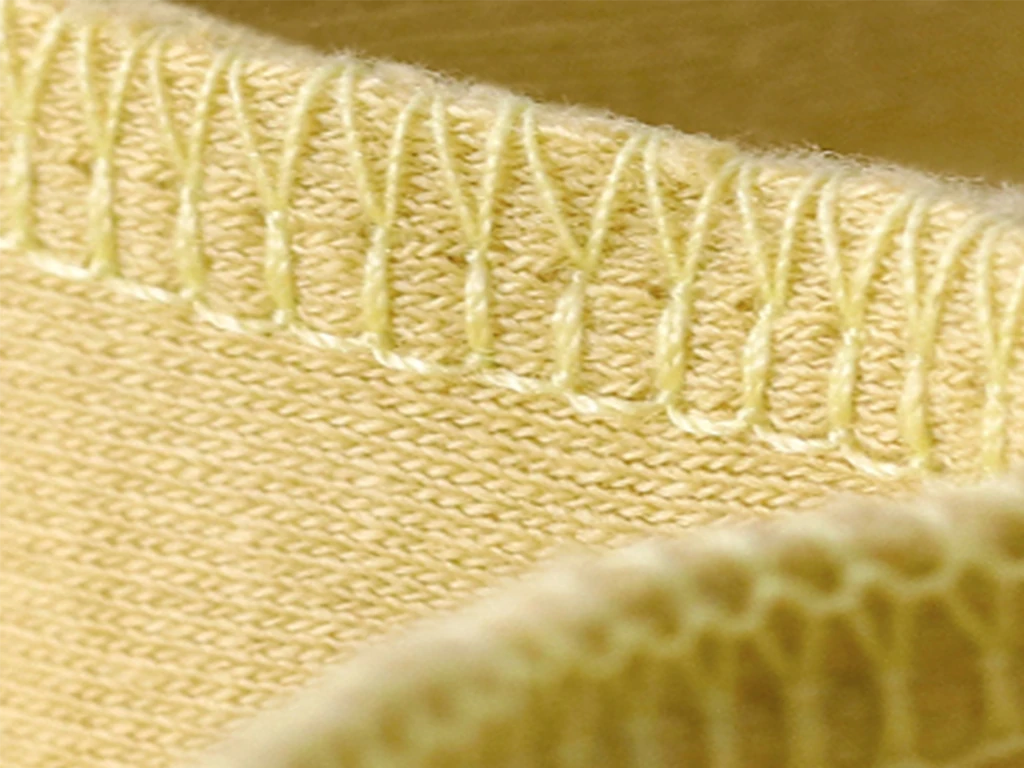

Application:Overlocking

Parameters

| Name | Sewing thread |

| Material | 100% polyester |

| Type | Thread |

| Technic | Dyed |

| Specification | 20s/2 20s/3 40s/2 40s/3(Customizable) |

| Length | 5000Y ,5000M ,4000Y ,4000M ,3000Y ,3000M |

| Twist | Customizable |

| Luster | Full-dull |

| Feature | Good color fastness, high toughness, low shrinkage, uniform twist, no nodules, good elongation, suitable for high-speed sewing |

Product

Production workshop

Video Introduction

Key Word

- polyester sewing thread

- 100 spun polyester sewing thread

Feature

The advantages of YM THREAD ‘s sewing thread

1、High strength: It is more durable than ordinary cotton and silk threads, and is not easy to break or damage.

2、Good wear resistance: The polyester fibers have good wear resistance, which means they can maintain their appearance and strength for a long time.

3、Good heat resistance: Polyester fibers have good heat resistance, which means they can maintain stability under high temperatures and are not easily deformed or melted. Therefore, they are suitable for clothing and fabrics that require high-temperature ironing or heat treatment.

4、Good light resistance: The polyester fibers have good light resistance, and are not easily discolored or yellowed. Products made with polyester threads can maintain their color for a long time even under sunlight exposure.

5、Good chemical stability: Polyester fibers are not easily affected by chemicals and are not easily damaged.

6、Rich colors: Polyester threads come in a variety of colors to meet different color needs.

7、Not easy to fade: The polyester fibers have good color fastness and are not easily faded.

8、Not wrinkled: Polyester threads are not easily wrinkled, which can maintain the smoothness of clothing.

9、Widely used: Polyester threads are mainly used in denim, sportswear, leather products, fur, and military uniforms, and are currently the most commonly used threads.

Application

Overlocking

Sewing

Shoes

Bag

swimwear

Color Card

More

What thread is best for sewing?

There are several types of threads that can be used for sewing, each with its own advantages and disadvantages. The best thread for sewing depends on the specific application and material being sewn.

Cotton thread is commonly used for general sewing and is a good choice for fabrics such as denim, canvas, and corduroy. It is strong and durable, but may not be suitable for high-stress applications or delicate fabrics.

Polyester thread is also widely used and is suitable for a variety of applications, including garments, home décor items, and craft projects. It is strong, resilient, and resists shrinkage and fading. However, it may not be suitable for all fabric types and can be rough on the thread.

Nylon thread is strong and elastic, making it suitable for sewing activewear, swimsuits, and other stretchable fabrics. It is also water-resistant and resists abrasion, but it may not be suitable for all fabric types and can be expensive.

In general, the best thread for sewing depends on the specific application, material being sewn, budget, and personal preference. It is important to match the thread type with the fabric type to ensure good results and durability.

How to produce sewing thread?

| Process Step | Explanation | Machines Used |

| Polymerization and chipping | The starting raw material for making polyester fibers is petroleum. Through polymerization, the petroleum is converted into polyester chips. | Polymerization reactor, chipper |

| Spinning | The polyester chips are melted and extruded through a spinneret to form fibers, which are then cooled and stretched to obtain polyester fibers. | Spinning machine, cooling tower, stretcher |

| Winding | The spun polyester fibers are wound into bobbins to facilitate further processing. | Winding machine |

| Twisting and ply-twisting | Single-ply fibers are twisted into multi-ply fine threads using a twisting machine, and then these fine threads are combined into a single or multi-ply coarse thread using a ply-twisting machine. | Twisting machine, ply-twisting machine |

| Dyeing, finishing, and coating | The ply-twisted polyester thread is dyed, finished, and coated to improve its performance and appearance. | Dyeing machine, finishing machine, coating machine |

| Packaging and final inspection | The processed polyester thread is packaged and undergoes final inspection to ensure product quality. | Packaging machine, inspection machine |