Shoes upper

(一)What is a fly-knit shoes upper?

Flyweave uppers are a type of upper made using flywire weaving technology. This technique relies heavily on 3D unibody molding technology, where yarns of various colors are used as raw materials and a new braiding process is used to weave a single-layer upper that is almost completely seamless. The most important features of fly-knit uppers are their lightness, fit and breathability.

Features of Flyknit Upper?

The use of this special weaving technology makes the upper highly breathable, which can effectively expel moisture and sweat from the shoe, keep the shoe dry, and effectively prevent foot odor and bacterial growth. At the same time, the fly-knit upper material is also lightweight and thinner than traditional materials, which is conducive to improving the wearer’s sports performance, reducing the burden on the feet and minimizing fatigue. In addition, the fly-knit upper material also has good toughness and wear resistance, after special treatment of the fly-knit material can effectively improve the wear resistance of the upper and extend the service life of the shoes.

(二)Who first invented fly-weaving?

Fly knit technology was first invented by Nike. Nike launched the fly knit technology called FLY KNIT in 2012, which is a technology that uses yarn fabrics, computer programmed to design the upper pattern, and then knitted together with the entire upper. Using 3D one-piece molding technology, FLY KNIT uses yarns of various colors as the raw material to weave an almost completely seamless single-layer upper that is lightweight, breathable, and fits the foot well. Upon its introduction, this technology has attracted widespread attention in the industry and popularity among consumers, and has spurred other sporting goods companies to follow suit and develop.

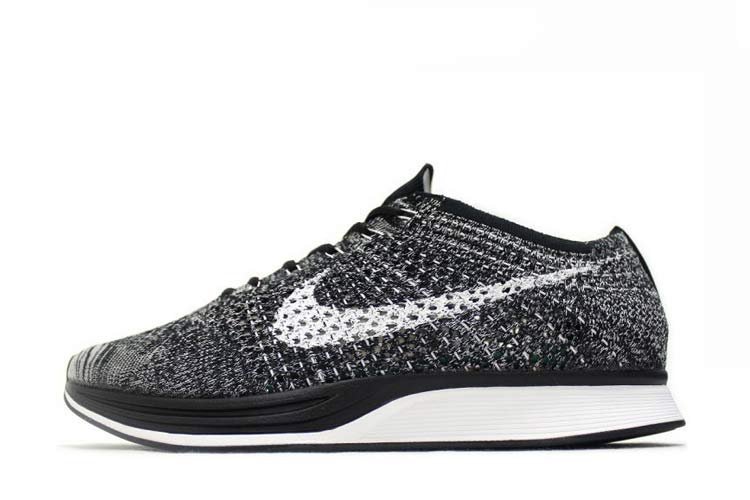

Nike Flyknit Racer Oreo 2

Nike Free Flyknit Mercurial

Air Jordan 31

Nike KD 9

(三)The material to be used for flyknit shoes uppers?

The materials used in fly-knit shoes uppers are diverse and mainly include blended fabrics such as chemical fibers, polyester、spandex and nylon. Such blended fabrics are characterized by the fact that their composition is not monolithic, but by the mixing of different materials to achieve specific performance requirements.

01-dope dyed polyester yarn

- Material :100 polyester

- Technic :dope dyed

- Denier :50-120d

- Filament:36-288f

- Intermingle:NIM SIM HIM MIM

02-dyed polyester yarn

- Material :100 polyester

- Technic :water dyed

- Denier :50-120d

- Filament:36-288f

- Intermingle:NIM SIM HIM MIM

03-high stretch yarn

- Material :100 polyester / 100 nylon

- Technic :dope dyed / hunk dyed /water dyed

- Denier :75D/36f/2 , 70D/24f/2 ,100D/24f/2

- Intermingle:NIM SIM HIM MIM

04-hot melt yarn

- Material :100 polyester / 100 nylon

- Technic :spinning

- Melting point :polyester 110-140°C

- Melting point :nylon 90°C-110°C

05-spandex covered yarn

- Material :100 polyester

- Technic :dope dyed / covered

- Filament :spandex 210-560d

- Filament :polyester 75-150d

06-air covered yarn

- Material :100 polyester / 100 nylon

- Technic :dope dyed / air covered

- Filament :spandex 20-40d

- Filament :polyester 75-150d

- Filament :nylon 70-150d

07-single covered yarn

- Material :100 polyester / 100 nylon

- Technic :dope dyed / traditional covered

- Filament :spandex 20-40d

- Filament :polyester 75-150d

- Filament :nylon 70-150d

08-monofilamnet yarn

- Material :100 polyester / 100 nylon

- Technic :Spinning

- Filament :0.08mm ,0.10mm, 0.12mm, 0.15mm

Related products

Production workshop display

Our polyester dyeing process assures color accuracy and batch reproducibility to ensure compliance .

The main difference between the two types lies in the number of yarns wrapped around the core yarn.

Texturing yarn is a critical process that enhances POY yarn to provide it with bulk and very elasticity.